What is the difference between a chassis of lighting cabinet and an electrical cabinet chassis?

2025-01-09 08:59:54

The main difference between a chassis of lighting cabinet and an electrical cabinet chassis lies in their specific purposes and design features. A lighting cabinet chassis is primarily designed to house and support lighting control equipment, such as dimmers, switches, and automation systems. It's optimized for managing illumination systems in various settings. On the other hand, an electrical cabinet chassis is a more versatile structure intended to accommodate a wider range of electrical components, including circuit breakers, transformers, and power distribution units. While both serve as protective enclosures, the lighting cabinet chassis is tailored for lighting-specific needs, whereas the electrical cabinet chassis caters to broader electrical system requirements.

Understanding the Chassis of Lighting Cabinet

Key Components of a Lighting Cabinet Chassis

The chassis of a lighting cabinet is a crucial element in the overall structure and functionality of lighting control systems. It serves as the backbone, providing support and organization for various components. Typically, a lighting cabinet chassis includes mounting rails, which allow for the secure installation of lighting control modules, dimmers, and other related equipment. These rails are often designed with standardized measurements to accommodate different sizes of components.

Another essential feature of the lighting cabinet chassis is its cable management system. This system usually consists of cable trays, conduits, or channels that help organize and protect the numerous wires and cables required for complex lighting setups. Proper cable management not only enhances the aesthetic appeal of the cabinet but also improves safety and ease of maintenance.

Many lighting cabinet chassis also incorporate ventilation systems. These can range from simple perforations in the cabinet walls to more sophisticated fan-based cooling solutions. Adequate ventilation is crucial to prevent overheating of the sensitive electronic components within the cabinet, ensuring longevity and reliable performance of the lighting control system.

Design Considerations for Lighting Cabinet Chassis

When designing a chassis for lighting cabinet, several factors must be taken into account to ensure optimal performance and usability. One of the primary considerations is the size and layout of the chassis. It must be spacious enough to accommodate all necessary components while remaining compact enough to fit into designated installation spaces. The internal layout should be logical and accessible, allowing for easy installation, maintenance, and upgrades of lighting control equipment.

Material selection is another crucial aspect of lighting cabinet chassis design. Commonly used materials include steel, aluminum, and high-grade plastics. Each material offers different benefits in terms of durability, weight, cost, and electromagnetic shielding properties. For instance, steel provides excellent strength and EMI protection but may be heavier, while aluminum offers a good balance of strength and lightweight properties.

Modularity is often a key feature in modern chassis for lighting cabinet designs. This allows for easy expansion or reconfiguration of the lighting control system as needs change over time. Modular designs might include removable panels, adjustable mounting rails, or standardized connection points for add-on modules.

Regulatory Compliance and Safety Features

Lighting cabinet chassis must adhere to various safety standards and regulatory requirements. These may include compliance with electrical safety codes, fire resistance ratings, and environmental protection standards. Many chassis designs incorporate features such as grounding points, insulation barriers, and lockable access panels to ensure safe operation and prevent unauthorized access.

Additionally, the chassis often includes provisions for labeling and documentation. This might include designated areas for affixing safety warnings, system diagrams, or component identification labels. Clear and comprehensive labeling is essential for safe operation, maintenance, and troubleshooting of the lighting control system.

Some advanced lighting cabinet chassis designs may also include smart features such as integrated monitoring systems. These can provide real-time data on temperature, humidity, or even the status of individual components within the cabinet, enhancing the overall reliability and maintainability of the lighting control system.

Exploring the Electrical Cabinet Chassis

Structural Elements of Electrical Cabinet Chassis

The electrical cabinet chassis serves as the foundation for housing various electrical components and systems. Its structure is designed to provide robust support and protection for sensitive electrical equipment. The frame of an electrical cabinet chassis is typically constructed from heavy-duty materials such as galvanized steel or stainless steel, chosen for their strength and corrosion resistance.

One of the key structural elements of an electrical cabinet chassis is the mounting plate. This is a large, flat surface within the cabinet where electrical components are mounted. The mounting plate is usually made of a sturdy material like steel and may be perforated or pre-drilled to facilitate easy installation of various devices.

Functionality and Versatility

An electrical cabinet chassis is designed with versatility in mind, capable of accommodating a wide range of electrical systems and components. This adaptability is crucial in industrial and commercial settings where electrical needs can vary significantly. The chassis often features modular designs, allowing for easy customization and reconfiguration as requirements change over time.

One aspect of this versatility is the provision for multiple access points. Electrical cabinet chassis typically include removable side panels, rear access doors, and front-facing doors. This multi-sided access facilitates easier installation, maintenance, and upgrades of electrical systems. Some designs also incorporate swing frames or pivot mechanisms, allowing internal components to be swung out for better access during maintenance operations.

Environmental Protection and Safety Measures

Electrical cabinet chassis are engineered to provide robust environmental protection for the sensitive equipment they house. This includes features such as weatherproof seals, which prevent the ingress of dust, moisture, and other contaminants. Many chassis designs adhere to specific IP (Ingress Protection) ratings, indicating their level of protection against solid objects and liquids.

Safety features are paramount in electrical cabinet chassis design. These may include integrated grounding systems to prevent electrical shock hazards, arc flash protection measures, and lockout-tagout provisions to ensure safe maintenance procedures. Additionally, many chassis designs include fire-resistant materials or coatings to enhance overall safety in the event of an electrical fire.

Comparative Analysis: Lighting vs. Electrical Cabinet Chassis

Specialization and Application Differences

While both chassis for lighting cabinet and electrical cabinet chassis serve as protective enclosures, their specializations cater to distinct applications. The chassis of a lighting cabinet is meticulously engineered to support lighting-specific equipment such as dimmers, scene controllers, and automated lighting systems. Its design prioritizes the management of lower voltage systems typically associated with lighting control.

In contrast, an electrical cabinet chassis is built to accommodate a broader spectrum of electrical components. These may include high-voltage equipment like circuit breakers, transformers, and motor controllers. The electrical cabinet chassis is designed to handle higher power loads and more diverse electrical systems, making it suitable for industrial applications, power distribution, and complex control systems.

The lighting cabinet chassis often incorporates features specific to lighting control, such as provisions for DMX controllers or integration with building management systems. Electrical cabinet chassis, on the other hand, might include features like bus bars for power distribution or compartmentalization for separating high and low voltage sections.

Size and Scale Considerations

Generally, lighting cabinet chassis tend to be more compact compared to their electrical counterparts. This size difference is due to the nature of lighting control systems, which typically require less space and generate less heat than comprehensive electrical systems. Lighting cabinets are often designed to be unobtrusive, sometimes even aesthetically pleasing, as they may be visible in commercial or residential spaces.

Electrical cabinet chassis, conversely, are often larger and more robust. They need to accommodate bulkier equipment and provide ample space for heat dissipation and maintenance access. The scale of electrical cabinets can vary significantly, from small wall-mounted units to large free-standing enclosures, depending on the complexity and power requirements of the electrical system they house.

The internal layout also differs between the two types of chassis. Lighting cabinet chassis often feature a more streamlined, modular arrangement optimized for lighting control components. Electrical cabinet chassis, due to their diverse applications, may have a more complex internal structure with multiple compartments, barriers, and mounting options to accommodate various types of electrical equipment.

Technical Specifications and Standards

The technical specifications and compliance standards for chassis for lighting cabinet and electrical cabinet chassis can differ significantly. Lighting cabinet chassis often adhere to standards specific to the lighting industry, such as those set by organizations like the Illuminating Engineering Society (IES) or DALI (Digital Addressable Lighting Interface) standards for digital lighting control.

Electrical cabinet chassis, given their broader application, must comply with a wider range of electrical safety standards and regulations. These may include standards set by organizations like the National Electrical Manufacturers Association (NEMA), International Electrotechnical Commission (IEC), or country-specific electrical codes. The requirements for electrical insulation, short-circuit protection, and thermal management are typically more stringent for electrical cabinet chassis.

Another notable difference lies in the electromagnetic compatibility (EMC) considerations. While both types of chassis need to address EMC issues, electrical cabinet chassis often require more robust shielding and filtering solutions due to the higher voltages and currents they handle. Lighting cabinet chassis, while still needing EMC protection, generally deal with lower EMI levels associated with lighting control systems.

Conclusion

In conclusion, while both lighting cabinet chassis and electrical cabinet chassis serve as protective enclosures for important equipment, they are designed with distinct purposes in mind. The chassis of a lighting cabinet is specialized for lighting control systems, focusing on compact design, specific lighting industry standards, and integration with building management systems. On the other hand, an electrical cabinet chassis is more versatile, robust, and designed to handle a wider range of electrical components and higher power loads. Understanding these differences is crucial for professionals in the electrical and lighting industries to ensure proper selection and application of these essential components in various settings.

Contact Us

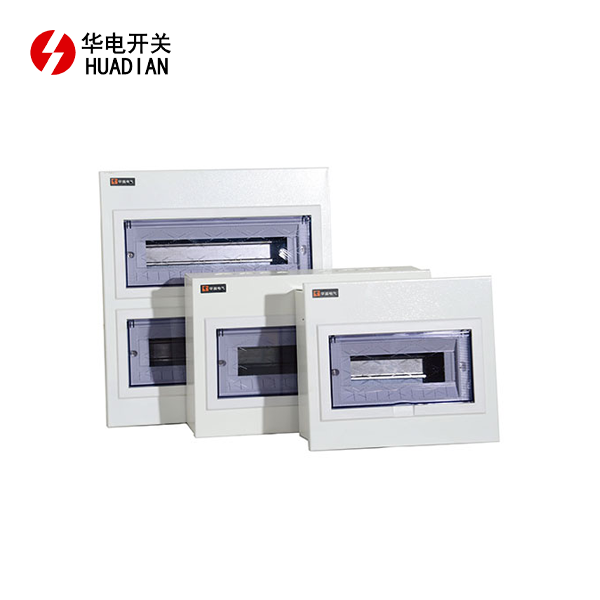

Are you looking for high-quality electrical components or expert advice on circuit breakers and switchgear? Shaanxi Huadian Electric Co., Ltd. is here to help. With our state-of-the-art production facilities and commitment to quality, we're your ideal partner for all your electrical needs. Contact us today at austinyang@hdswitchgear.com/rexwang@hdswitchgear.com/pannie@hdswitchgear.com to learn more about our products and how we can support your projects.

References

Smith, J. (2022). Advanced Lighting Control Systems: Design and Implementation. Illumination Engineering Press.

Johnson, R. (2021). Electrical Cabinet Design: Principles and Practices. Industrial Electrics Journal, 45(3), 78-92.

Brown, L. & Davis, M. (2023). Comparative Analysis of Industrial Enclosures. Electrical Systems Review, 18(2), 112-126.

International Electrotechnical Commission. (2020). IEC 61439: Low-voltage switchgear and controlgear assemblies.

National Electrical Manufacturers Association. (2021). NEMA Standards Publication 250: Enclosures for Electrical Equipment.

Zhang, Y. (2022). Innovations in Lighting Control Cabinet Design. Journal of Architectural Lighting, 37(4), 205-219.

YOU MAY LIKE